Non-thermal safety for liquids that matter

FloUV brings precision UV-C processing to opaque liquids—protecting quality, nutrition, and value.

When liquids stay alive

With FloUV non-thermal UV-C processing, liquids move as they should—flowing naturally while being made safe, without heat, pressure, or disruption.

Native proteins remain intact, bioactives stay functional, and quality is preserved—allowing liquids to retain their natural structure, nutrition, and value

FloUV is a non-thermal UV-C processing platform engineered to deliver uniform microbial inactivation in opaque and viscous liquids. By integrating precise UV-C dose control with advanced fluid-dynamics design, FloUV achieves safety targets without heat—preserving native proteins, bioactives, and functional quality.

Differentiate Your Products with Non-Thermal FloUV Processing

With FloUV, liquids flow as they should—moving naturally through the process while being made safe by light, not heat. Proteins remain native, bioactives stay functional, and quality is preserved, allowing liquids to retain their structure, nutrition, and value—just as intended.

Lactoferrin and IgA are heat-sensitive milk bioactives that are significantly degraded during conventional thermal processing due to protein denaturation. FloUV preserves these bioactives by achieving microbial safety without heat, maintaining up to ~80% of native lactoferrin and IgA activity through non-thermal UV-C treatment.

Learn how FloUV preserves milk bioactives through non-thermal processing—and how progressive dairy processors are leveraging this capability to develop value-added products such as lactoferrin and IgA while maintaining native functionality.”

Preserving Milk Bioactive

— Former CustomerPerformance Matters

Process Efficiency

FloUV delivers precise, non-thermal UV-C treatment with low energy demand—reducing thermal load, preserving product value, and improving overall operational efficiency in complex liquid processing.

Easy Integration

FloUV is designed for seamless integration into existing processing lines, working alongside thermal, membrane, and aseptic systems. Our team provides end-to-end technical support, from system integration and commissioning to validation and scale-up.

Whether you’re a processor looking to innovate your product line with non-thermal solutions, or an OEM or distributor aiming to expand your portfolio with next-generation liquid processing technology, we offer FloUV platforms and partnerships tailored to your operational and business model.

Solution for brand and manufacturer.

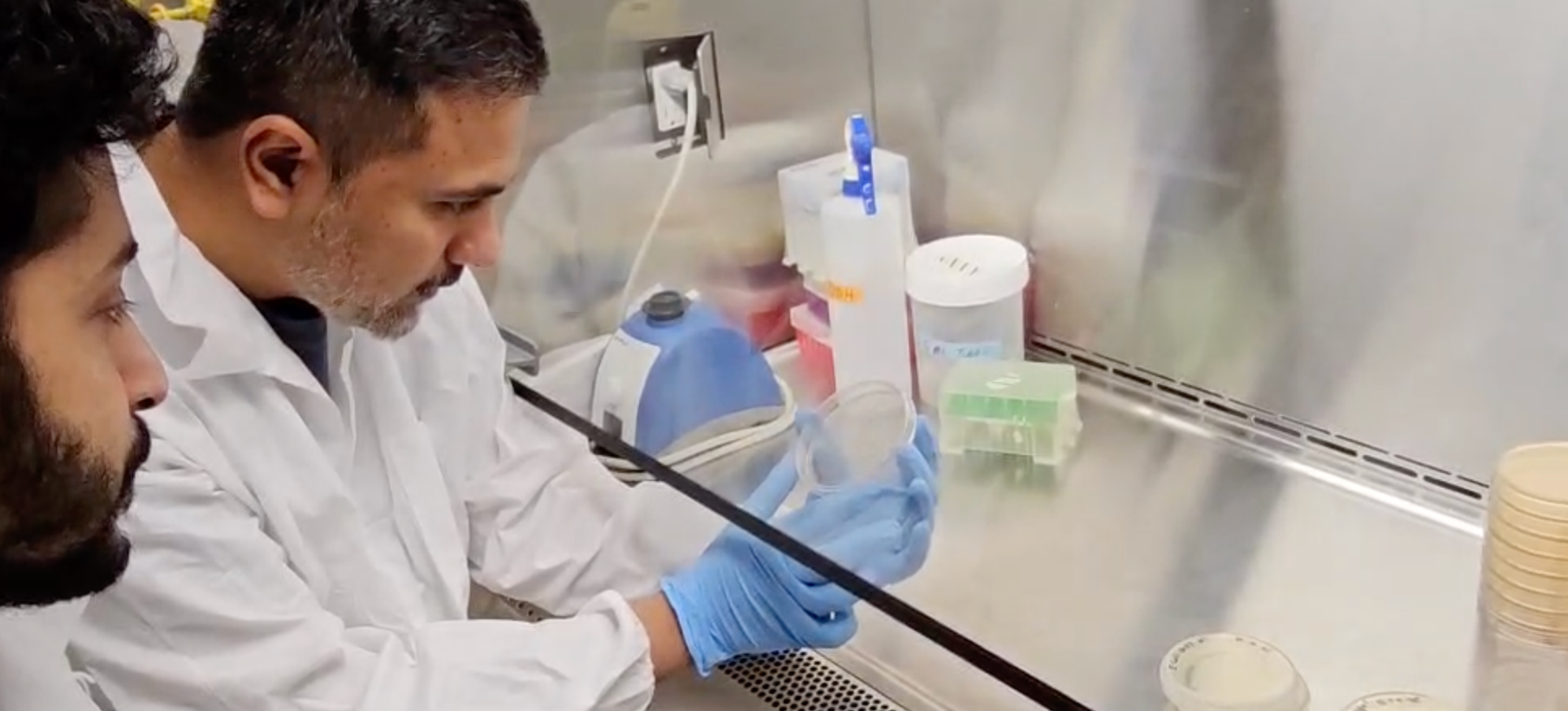

Technology

Harnessing the principles of light–matter interaction and advanced fluid dynamics, Dr. Ankit Patras pioneered a new approach to overcome the fundamental limits of conventional UV treatment in opaque and viscous liquids.

The FloUV platform integrates this breakthrough science into industrial non-thermal UV-C systems, enabling precise, uniform microbial inactivation without heat

Built on rigorously validated research and translated from laboratory discovery to real-world processing, FloUV delivers microbial safety while preserving native proteins, bioactives, and functional quality. Explore the science behind FloUV technology.

Got any questions?

Are you ready to unlock new value from your liquid processing operations and gain a competitive edge with non-thermal UV-C technology? Let’s collaborate to integrate FloUV into your existing systems and expand what your product line can deliver.

Get in touch—we’re here to help.

Book a meeting with us or reach out directly to our team via email or LinkedIn.

The FloUV processing insights blog

If you’re interested in learning more about FloUV technology, real-world case studies, and non-thermal processing solutions across dairy, beverages, and functional ingredients, explore our latest articles and insights below.

-

How Non-Thermal UV-C Is Transforming Cheese Brine Safety and Sustainability

-

Precision UV-C as a Pre-Treatment Kill Step in Beverage Flavoring Systems A Science-Aligned Application Case for Sugar Syrups and Fruit Juice Bases

-

Reinventing Fresh Apple Cider Processing with Non-Thermal UV-C Technology